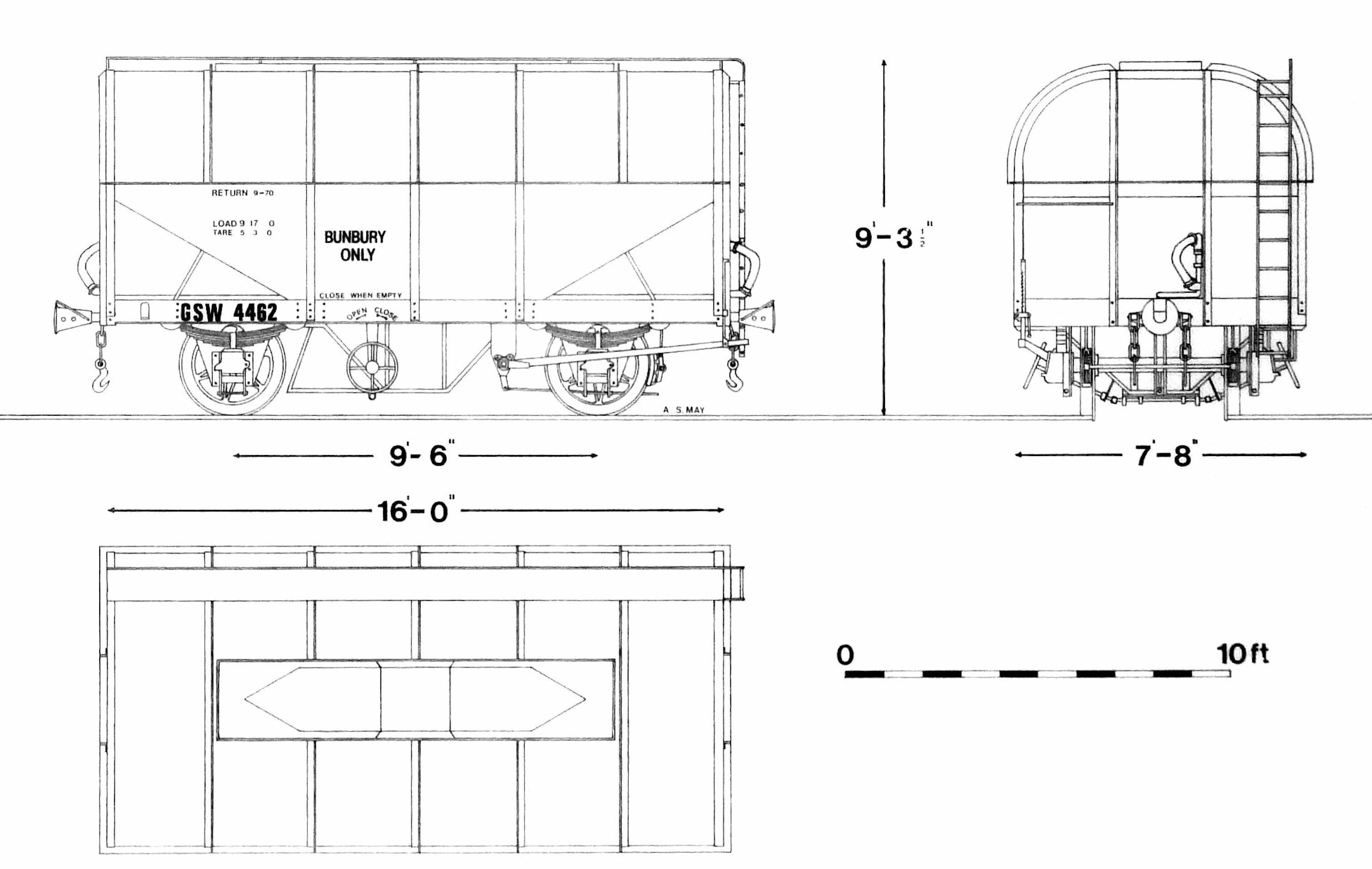

| Class GSW Wheat Hoppers |

|

WAGR official photo of GSW6456 (RHWA collection) |

|

250 GS class wagons were built between 1935 and 1942 by Midland workshops. These paired the GC body with a new type of steel underframe and followed on from the steel underframe version of the GC class. Some were later given wooden floors as class GST. A more radical conversion to GSW class grain hoppers began in 1963. The wagons were converted as follows with 318 being the prototype. |

| 1963 | 318, 2550, 5058, 6379, 6456, 7580, 9855 ex GS |

| 1964 | 1391, 1473, 2298, 2446, 2527, 5021, 5032, 5041, 5043, 5044 ,6345, 6459, 6465, 6478, 6589, 6773, 7919, 7953, 8968, 9255 ex GS

330, 2398, 3858, 4462, 6645 ex GST |

| 1965 | 330, 2398, 3858, 4462, 6645 ex GST |

|

However it was not all plain sailing. Les Smith (then a young draughtsman) takes up the story: They set-up the prototype GSW (may have been three or four) (ASM note: there were - 318, 2550, 5088 & 6379) and sent them to North Fremantle for load and discharge trials after running them up the long yard and back. The grain leaked from the side "flap" type doors. WAGR official photo of the GSW prototype (RHWA collection) All work was halted on the remainder as they had been progressing thru the shops. I was asked / told to take a look and it was pretty obvious that there would be problems due to the flatness of the sides and that the doors for the GW (all wood etc) were much more forgiving......rubber seals were not an answer as they get worn off or torn away from the grain pouring out. I tried to modify the cam fingers that held the flaps closed by adding torsion to the shaft to sequentially push on each flap. This showed promise. The re-trial was better. Changed to a spring steel shaft with greater torsion and problem solved thus allowing the wagon to go to Bunbury. Bunbury was a disaster as the wagon would not pass thru the portal frames of the grain loader which had once been a crane. The GS underframe was much wider than the original wooden GW. With my Section Leader we were rushed down to Bunbury in a chauffer driven government car. It was agreed there and then that they would remove the protruding angle frame legs to gain some 70mm of "gap" and place some thin steel sheeting on the portal inside to give a smooth surface to prevent the operator getting caught. We would take the legs off the outside angle framing of the GSWs but the cam fingers and shaft had to go. Thus we went to a bottom discharge and a saving in that only one person was required for a "dump" in lieu of two. The sheeting allowed for discharge in the rain. We made the changes at Midland with work progressing immediately with the 70 odd wagons being stripped and sides "smoothed" etc. The bottom door plate was thin cast steel with the rack teeth cast integral to save depth due to clearance problems. A beaut little wagon was born! A couple of years later we had a phone call from Collie with 4 GSWs kicked off a train for thin tyres. This was a surprise as they should not have been on the mainline due to no brake system and "condemned" wheels only for yard use. The grain boys had worked out that they could send 4 per 40 wagons across to Narrogin etc as operations allowed 10% brakes cut-out. This saved tarpaulins and not having to shovel and sweep the grain out. The GSWs were going every-where when there was no ship to load! I started to draw a vacuum brake installation as room had been made at the end(s) to fit such. I was told to stop and so passed away any future proliferation of small hoppers and modernisation, efficiency etc. |

|

GSW5021 Photo Joe Moir |

|

GSW5023 with roof hatch open. Photo B Morrell. RHWA collection |

| This class is another example where a more logical and consistent use of the classification system would have put these wagons in the "L" group with the other four-wheeled hoppers. With the exception of 5058 written off in 1981 all of the GSW class hoppers were written off in 1982. |